Grow Your Business with a Vertically Integrated Supplier

If you need wear-resistant parts and tools made of tungsten carbide (WC) for applications related to Agriculture, Ammunition Tooling, Automotive, Can Tooling, Fastener Tooling, Lamination Tooling, Oil & Gas Components, Powder Metal Compaction (PM), or Stamping, it pays to work with a vertically integrated manufacturer. That’s because a production process that occurs under one roof instead of at multiple locations accelerates procurement cycles, makes rigorous quality control easier, and reduces your total cost of ownership (TCO).

By trimming lead times, due to less time required to ship products, you can receive your orders in a timely fashion rather than weeks or months. This abbreviated timeframe can be crucial in meeting your production deadlines. Aligning with a supply chain partner also gives you the ability to closely monitor and participate in the quality assurance process to make sure your products meet the required specifications, safety standards, and other criteria.

Additionally, you can reduce shipping costs, tariffs, port taxes, and additional handling fees that can add cost without adding value.

Your ideal supply chain partner will recommend the best grade of powder for your application, compact and shape the material into a green stage, control the dimensional shrinkage while sintering, and finish it to meet the most exacting specifications.

Your ideal supply chain partner will recommend the best grade of powder for your application, compact and shape the material into a green stage, control the dimensional shrinkage while sintering, and finish it to meet the most exacting specifications.

By working with a partner such as General Carbide, you can reduce your TCO, decrease direct costs by experiencing longer part or tool life, expect shorter lead times & on-time delivery, and decrease your need for working capital and inventory.

As a vertically integrated partner, we are a proven source of improved control over costs and production cycles; better supply chain coordination; excellent market responsiveness; reliable and secure sourcing of raw materials; streamlined innovation; and greater competitive advantage. Engaging in a relationship with such a partner puts you in a stronger position to meet your customers’ needs and win repeat business that is easier and less expensive to serve than new business.

It's one thing to have the desire to work with a reliable supply chain partner and another thing to make that vision a reality. Based on our experience, the best relationships result from customers taking these 10 actions when looking for a supply chain partner:

It's one thing to have the desire to work with a reliable supply chain partner and another thing to make that vision a reality. Based on our experience, the best relationships result from customers taking these 10 actions when looking for a supply chain partner:

- Define Requirements. Enable your partner by defining or refining your product specifications, quality standards, expected volume, and projected budget.

- Research Potential Partners. Look for companies with a proven track record in your industry. Seek recommendations and read reviews. With the web, that information is more accessible than ever.

- Evaluate Capabilities. Assessing equipment, technology, and expertise is critical to establishing a mutually beneficial partnership.

- Visit Facilities. Get a firsthand look at the potential partner’s operations. The time and money you invest in that activity can provide insight into their operational efficiency, business practices, and organizational culture. At General Carbide, we welcome onsite visits at mutually convenient times.

- Verify Certifications and Compliance. Ensure that your potential partner has the necessary certifications, such as ISO, and complies with relevant industry standards and regulations.

- Assess Quality Control Processes. Inquire about a potential partner’s quality control procedures and ask them how they handle challenges such as defects and non-conformities. Their answers should be highly detailed. If they are not, keep “pressing” until you get a satisfactory answer.

- Review Past Work. Ask for case studies or examples of similar work the supplier has completed. This step in the selection process can help you gauge your potential partner’s relevant experience and reliability.

- Evaluate Communication Skills and Responsiveness. Determine how well a supplier keeps you informed about what’s happening with your account, and in language you can understand.

- Evaluate Financial Stability. Ensure that your prospective manufacturing partner is financially stable and capable of supporting your long-term production needs, so you don’t have to scramble to find a replacement due to unforeseen circumstances.

- Negotiate Terms and Agreements. Clearly define the terms of your partnership in writing, and if appropriate use an attorney to draw up the agreement so terms and conditions (T&C), including pricing, lead times, delivery schedules, and intellectual property rights, are documented in a contract.

Technical Experts with a Heart

Besides having a strong business sense based on decades of experience, we are skilled engineering and manufacturing professionals with a breadth and depth of technical knowledge and production versatility that is difficult to find anywhere else. What’s most important to us, however, are the long-term relationships we form and maintain with each of our customers so we can benefit them to the greatest extent possible. As a company that has been in business for more than 55 years, we go back a long way with many of our customers.

The high degree of loyalty our customers show us results from our taking the time to learn about our customers’ businesses and ask the right questions upfront. As a result of those efforts, we get to know our customers and their applications better than other manufacturing partners typically do. Our endless curiosity and commitment to excellence allow us to engineer the ideal wear parts or tools our customers need to meet their production goals.

By understanding our customers’ respective market niches, sharing similar values, making certain we have the capacity and resources to serve each customer exceptionally, establishing the reliability and financial stability of our trading partners, and determining that there is strong potential for collaboration and growth, is an approach that we have used successfully, and we welcome the opportunity to help our customers use that strategy to their competitive advantage.

A Product Primer

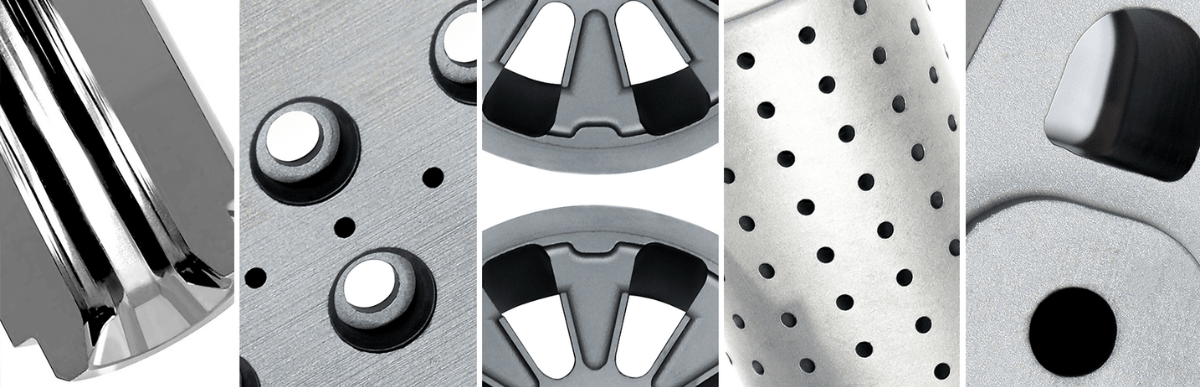

At General Carbide, the tungsten carbide (WC) composite material we produce is available in dozens of grades that are formulated to specifications for most applications.

The process we use to make WC, also known as cemented carbide, is called powder metallurgy. The term “cemented” refers to the tungsten carbide particles captured in the metallic binder material and “cemented” together to form a metallurgical bond between the WC particles and the cobalt (Co) binder (WC-Co) in the sintering process.

The process we use to make WC, also known as cemented carbide, is called powder metallurgy. The term “cemented” refers to the tungsten carbide particles captured in the metallic binder material and “cemented” together to form a metallurgical bond between the WC particles and the cobalt (Co) binder (WC-Co) in the sintering process.

WC powder, generally ranging in proportion to 70%-97% of the total weight of the part or tool, is mixed with a binder material, usually cobalt or nickel, and sintered in a furnace. Sintering is the process we use to make a powdered metal into a solid or mass by heating it and compressing it with hot isostatic pressing (HIP). Sinter-HIP is a method of thermal consolidation for cemented carbide that results in a product that contains little or no porosity and helps to maximize quality and operating life.

Investing in Our Customers & Future Workforce

To help ensure the long-term success of our customers, we have applied our engineering and manufacturing expertise to a recent capital expansion, which included a brand new 50,000-square-foot production facility to house our finishing operations.

By purchasing and renovating the building and adding another 14,000 square feet to the structure, we improved efficiency by consolidating our operations on a single campus, expanding capacity, and eliminating the need to use several facilities we had outgrown in nearby industrial parks. We also have the flexibility to expand by an additional 12,000 square feet if needed.

To staff the facility, we created positions in management and production, including machinists, supervisors, managers, and custodians. The shop floor features an array of equipment, including grinders, lathes, EDM machines, inspection systems, a cleanroom, and a dust reduction system. This investment demonstrates our optimism about our future.

.jpg?width=401&height=226&name=GCCA%20Photo%20%232%20(1).jpg) The expansion tracks with our values, which include a commitment to work together as a cohesive team, exceeding our customers’ expectations for quality and performance, continually improving our products and processes, always delivering orders on time, and completing orders without defects. All those goals are our way of bringing out the best in ourselves as a company and as individual team members by continually adhering to the motto WE CAN!

The expansion tracks with our values, which include a commitment to work together as a cohesive team, exceeding our customers’ expectations for quality and performance, continually improving our products and processes, always delivering orders on time, and completing orders without defects. All those goals are our way of bringing out the best in ourselves as a company and as individual team members by continually adhering to the motto WE CAN!

We created the General Carbide Career Academy to strengthen our team members’ abilities to serve customers. It consists of in-depth courses that our plant managers have developed for new team members, and weekly classes for established ones, to hone their skills and develop new ones. Courses offered at the Academy include Best Quality Practices for 5S Lean Manufacturing; Use of Calipers & Micrometers; Math for Manufacturing; CNC Programming, Milling & Lathe; and Print Reading. We also offer professional development classes on a variety of subjects, including Advanced Machining, Training with Live Tooling, G-Code, Leadership, Communication, and Safety.

.jpg?width=295&height=166&name=GCCA%20Photo%20%236%20(1).jpg) Additionally, we are enhancing efforts to shorten the learning curve of high school students that we recruit out of school to begin their careers with us upon graduation. Those individuals are also participating in the GCCA.

Additionally, we are enhancing efforts to shorten the learning curve of high school students that we recruit out of school to begin their careers with us upon graduation. Those individuals are also participating in the GCCA.

Sharing Our Knowledge in a User-Friendly Way

As industry professionals who are committed to providing customers with useful information that can lead them to make informed purchasing decisions, we have created a comprehensive Resource Library on our website. It includes technical literature about our general and market-specific capabilities and contains ad reprints with a lot of useful content, as well as safety data sheets.

Foremost among our resources is The Designer’s Guide to Tungsten Carbide. This 60-page comprehensive document is available for downloading and provides background information on cemented carbide; summarizes the material’s mechanical, thermal, electrical & magnetic, and corrosion properties; explains design considerations when designing tungsten carbide parts or tools; offers insights into attaching and assembling of cemented carbide parts; describes finishing techniques such as grinding, electrical discharge machining (EDM); and provides charts related to grade specifications, metric conversions, and grit sizes.

Foremost among our resources is The Designer’s Guide to Tungsten Carbide. This 60-page comprehensive document is available for downloading and provides background information on cemented carbide; summarizes the material’s mechanical, thermal, electrical & magnetic, and corrosion properties; explains design considerations when designing tungsten carbide parts or tools; offers insights into attaching and assembling of cemented carbide parts; describes finishing techniques such as grinding, electrical discharge machining (EDM); and provides charts related to grade specifications, metric conversions, and grit sizes.

The Designer’s Guide, in its completeness, illustrates the premium we put on relationships with our customers. It also shows our ability to select the best grade of tungsten carbide to meet the most demanding applications and specifications. To benefit from our unique combination of engineering and manufacturing expertise, commitment to quality, and deep concern for the success of our customers...